Part 7: Electronics

Share

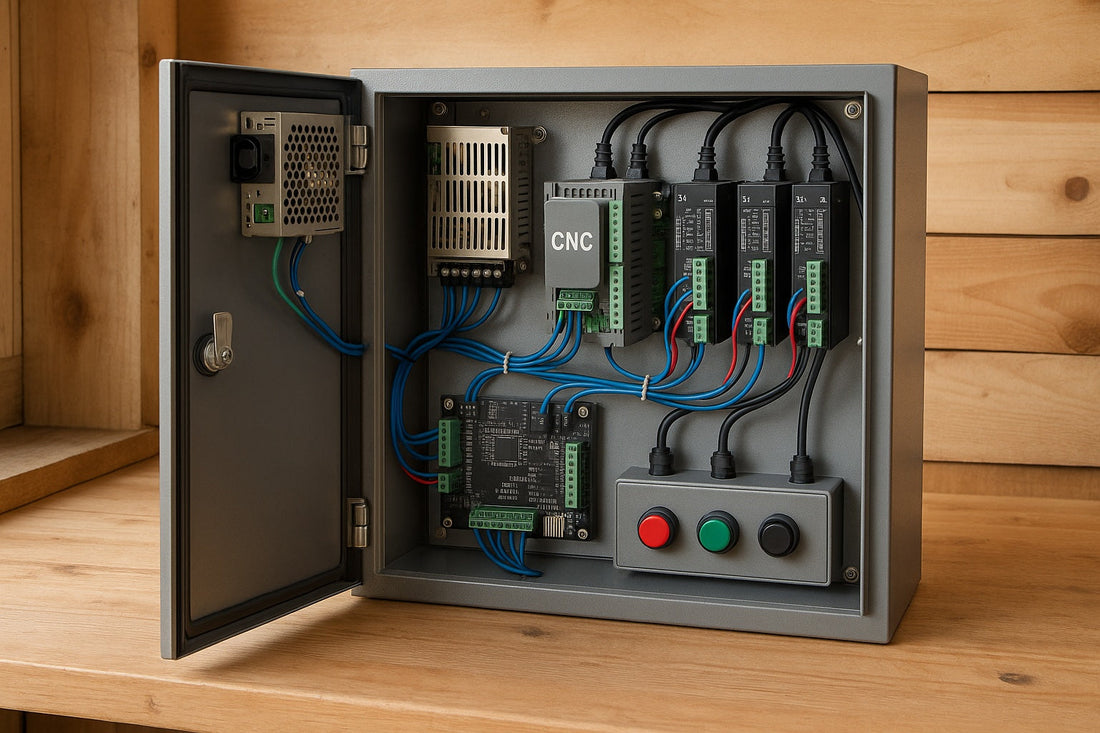

Core Components of a CNC Plasma Electronics System

1. Motion Controller

The main “motherboard” of your machine — it runs the code for your machine and interacts with all the other connected electronics.

2. Power Supplies

Provide the correct voltage and current for motors, drivers, logic boards, and accessories.

3. Stepper or Servo Motors

Physically move the X, Y, and Z axes.

4. Motor Drivers

These take the motion signals from the main controller and convert them to a signal that is powerful enough to move the motors — they convert low-voltage control signals into high-current pulses that move the machine.

5. Limit Switches

Tells the machine when its at the end of an axis so it can stop before crashing. These are also used to ‘home’ the machine.

6. Initial Height Sensing (IHS)

Automatically determines where the top of your material is before a cut.

7. Torch Height Control (THC)

Automatically adjusts Z-height during cutting to maintain the correct distance from the material — this is critical for consistent cut quality on warped or uneven sheets.

8. Emergency Stop (E-Stop)

Cuts power instantly — an essential safety feature for any CNC system.

Choosing Your Electronics Setup

1. Motion Controllers

Your motion controller is responsible for reading G-code and sending timed step/direction pulses to the drivers. For plasma, THC support is vital — which means G-code-based systems are generally required.

Off-the-shelf Controllers:

- Mach3 / Mach4 (Windows-based) — legacy but still widely used.

- Masso G3 — all-in-one controller, no PC needed, decent THC support.

- OpenBuilds BlackBox — great for beginners, though THC is limited.

- Centroid Acorn — strong THC integration, Windows-based.

- C&CNC Plasma Systems — plasma-specific, pre-configured with THC options.

DIY/LinuxCNC Approach:

- Mesa Cards (e.g. 7i96S, 7i76E + THCAD) + LinuxCNC — most flexible and powerful, but requires setup knowledge.

- Excellent THC integration, ideal for advanced or budget-conscious builders.

Tip: Generally avoid Grbl-based boards for plasma — most can’t handle Torch Height Control or arc voltage feedback.

2. Power Supplies

You will likely need multiple power supplies:

- 24V or 36V for motors and drivers

- 5V, 12V or 24V for logic-level components.

Types:

-

Switching Power Supplies (SMPS):

Compact, efficient — most common in DIY builds.

Ensure they are earthed properly to reduce EMI.

-

Toroidal Transformers:

Large, heavy, and expensive, but offer clean, linear power with less electrical noise.

Tip: Keep your logic power separate from your motor power to reduce interference.

3. Motors: Stepper vs Servo

-

Stepper Motors (most common):

Simple, cheap, reliable. Plenty of torque for plasma tables.

Great for most DIY builds.

-

Servo Motors (premium choice):

Faster and more precise with feedback loops which means they know exactly where they are.

However more complex and expensive.

4. Motor Drivers

Motor drivers power the motors and receive step/direction signals from the controller.

Choose drivers that match your motor voltage/current and are compatible with your controller’s output type (e.g., 5V logic signals).

Most hobby plasma builders use external stepper drivers (e.g., DM542, Leadshine, Gecko) or integrated systems.

5. Limit Switches

Used to prevent crashes and set machine home positions.

Types:

- Mechanical: Cheap, reliable, but can ‘bounce’.

- Optical: More precise, but more sensitive to dirt and alignment.

- Proximity Sensors: No contact needed — great for industrial builds.

Tip: Enable debounce (hardware or software) to filter out false triggers for mechanical switches.

6. Initial Height Sensing (IHS):

Determines material surface before the cut.

- Options:

- Ohmic sensing: Conductive material contact — very accurate.

- Mechanical switch (floating head): Simpler, more common.

- Both (Ideal): Ohmic sensing for accurate measurement, floating head for backup.

7. Torch Height Control (THC):

Adjusts torch height during cutting, based on arc voltage.

Why it's essential:

- Warped or uneven sheets = inconsistent cuts if height isn't adjusted on the fly.

- THC keeps the arc stable — extending consumable life and improving cut quality.

Types:

-

Standalone THC modules: (e.g. Proma THC)

Easy to add to many systems.

-

Integrated (e.g. Mesa THCAD with LinuxCNC):

More accurate and tightly synced with motion control.

8. Torch Protection

CNC plasma tables can crash — protect your torch:

-

Magnetic Breakaway Mounts:

Let the torch safely detach on collision.

-

Crash Detection Sensors:

Pause the job if the torch hits something.

Best Practices for Noise and Interference Mitigation

Plasma systems are notoriously noisy (electrically). Follow these guidelines to avoid erratic behaviour:

- Use shielded cable for all signal lines (limit switches, step/direction, THC).

- Use inline EMI filters on your AC power input.

- Ground the shields at one end only (usually at the controller cabinet).

- Keep signal and power cables separate — cross at 90° if they must touch.

- Use 12 or 24V where possible for signal wires - less susceptible to EMI.

- Twisted pair wiring helps cancel out interference.

- Avoid loops and excess slack — long unshielded wires = antennas.

- Use proper strain relief and cable chains for movable axes.

- Ground everything properly — frame, power supply chassis, controller cabinet.

Note: If you follow all of these and still have EMI issues, A last ditch attempt can be to use ferrite beads on signal lines.

Check out the LinuxCNC Best Wiring Practices for a great resource on this.