Part 2: Foundation Knowledge

Share

What is Plasma and How Does it Cut Metal?

Before we get into the machines, let’s start with what plasma actually is.

Most of us are familiar with solids, liquids, and gases — like ice, water, and steam. These states change with energy — add heat to ice and it becomes water, then steam. But if you add even more energy to a gas, it changes again: it becomes ionised.

In this ionised state, the gas is full of free electrons and charged particles — and that’s what we call plasma. It’s the fourth state of matter, and what makes it special is that plasma can conduct electricity and respond to magnetic fields.

In plasma cutting, we take a gas (often air or nitrogen), energise it into plasma using electricity, and push it through a narrow nozzle at high speed. The plasma arc reaches temperatures around 28,000°C — hot enough to melt metal instantly. At the same time, the force of the gas blows the molten metal away, cutting through the material cleanly and quickly.

What is a CNC Plasma Cutter?

A CNC plasma cutter is very simply a plasma torch mounted to a machine that moves around, following a set of instructions — using a computer to guide the torch along a programmed path.

Instead of moving the torch by hand, the CNC (Computer Numerical Control) system moves the torch around, following a digital design created by the user. It moves in X, Y and Z directions to cut out the desired pattern from sheet metal. This automation means you can create precise, repeatable metal parts such as custom brackets, signage, intricate art and fire pits, to name a few.

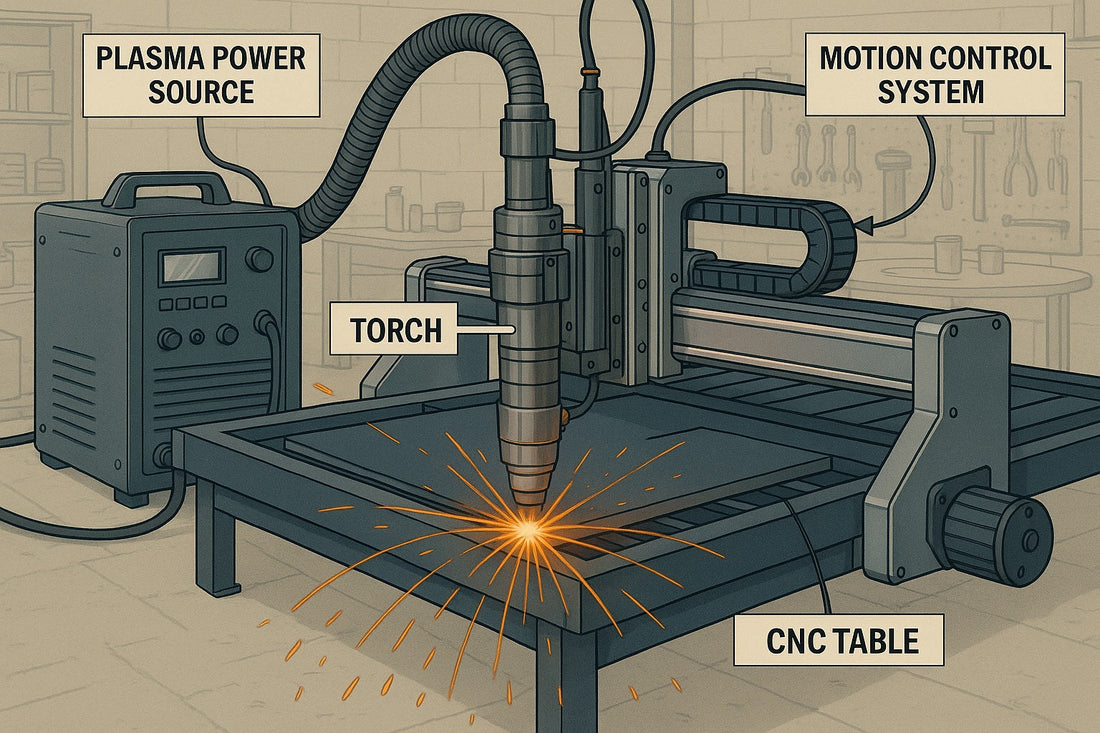

A CNC plasma system typically includes:

- A plasma power source - to create the arc,

- A torch - to focus the plasma,

- A CNC table - for holding the material and moving the torch

- A motion control system - the electronics or the brain to control the table,

- a compressed air system to supply and filter the air/gas.

What Can I Do With a CNC Plasma Cutter?

CNC plasma cutters are incredibly versatile. You can:

- Cut steel, stainless steel, and aluminium plates,

- Make brackets, gussets, and structural parts,

- Create signs, artwork, and decorative panels,

- Build custom parts for vehicles, machinery, and fabrication projects,

- Prototype designs quickly and in-house.

Whether you’re working on a home workshop project or small-batch production, a CNC plasma cutter opens up a lot of possibilities for working with metal.

What Materials Can You Cut With a CNC Plasma Cutter?

Plasma cutters work on electrically conductive materials.

That typically includes:

- Mild steel,

- Stainless steel,

- Aluminium,

- Copper,

- Brass.

What Plasma Cutters Don’t Cut:

- Any Non-conductive material (like wood, plastics, glass) — plasma won’t work at all.

- Very very thick metals — while plasma is great up to around 25–30mm thickness (depending on the machine, we will touch on this more later), much thicker materials can be better suited to other methods like oxy-fuel.

- Very very thin metals - whilst plasma cutters can cut thin metals, laser cutting can be a better choice for higher accuracy.

What is G-code?

G-code is the language most CNC machines use to move. It’s a set of simple instructions that tell the machine exactly where to go, how fast, and when to cut

For plasma cutting, G-code typically controls:

- Torch on/off,

- Movement along X, Y, and Z axes,

- Cutting speeds (feedrate),

- Pierce timing (how long the arc stays in one spot to pierce the material).

Example of Simple G-code for Plasma Cutting:

G21 ; Set units to millimetres

G90 ; Absolute positioning

M03 ; Torch on

G01 X100 Y0 F1500 ; Move to X100 Y0 at feedrate 1500mm/min

G01 X100 Y100 ; Move to X100 Y100

G01 X0 Y100 ; Move to X0 Y100

G01 X0 Y0 ; Move back to start

M05 ; Torch off

Don’t worry if it looks intimidating — G-code is usually generated automatically using software called CAM software which stands for Computer Aided Manufacturing. But understanding the basics can sometimes help you troubleshoot and fine-tune.

Common CNC Plasma Jargon Explained

A quick glossary to help you get started:

- Kerf: The width of the cut made by the plasma arc.

- Pierce Delay: The time the torch waits after starting the arc before beginning to move — lets the arc fully pierce the material.

- Feedrate: The speed the torch moves while cutting, usually in mm/min.

- THC (Torch Height Control): Automatically adjusts torch height to keep a consistent distance from the material.

- IHS (Initial Height Sensing): Detects the surface of the material before starting a cut.

- Cut Chart: Manufacturer-provided settings for amperage, speed, and gas flow based on material thickness.

- Dross: Molten metal that solidifies on the bottom edge of the cut — common but manageable.

- Consumables: The nozzle, electrode, and other parts of the torch that wear out and need regular replacement.

- Pilot Arc: A small arc that forms inside the torch before the main cutting arc — helps start the cut without needing direct contact.