Part 4: System Overview

Share

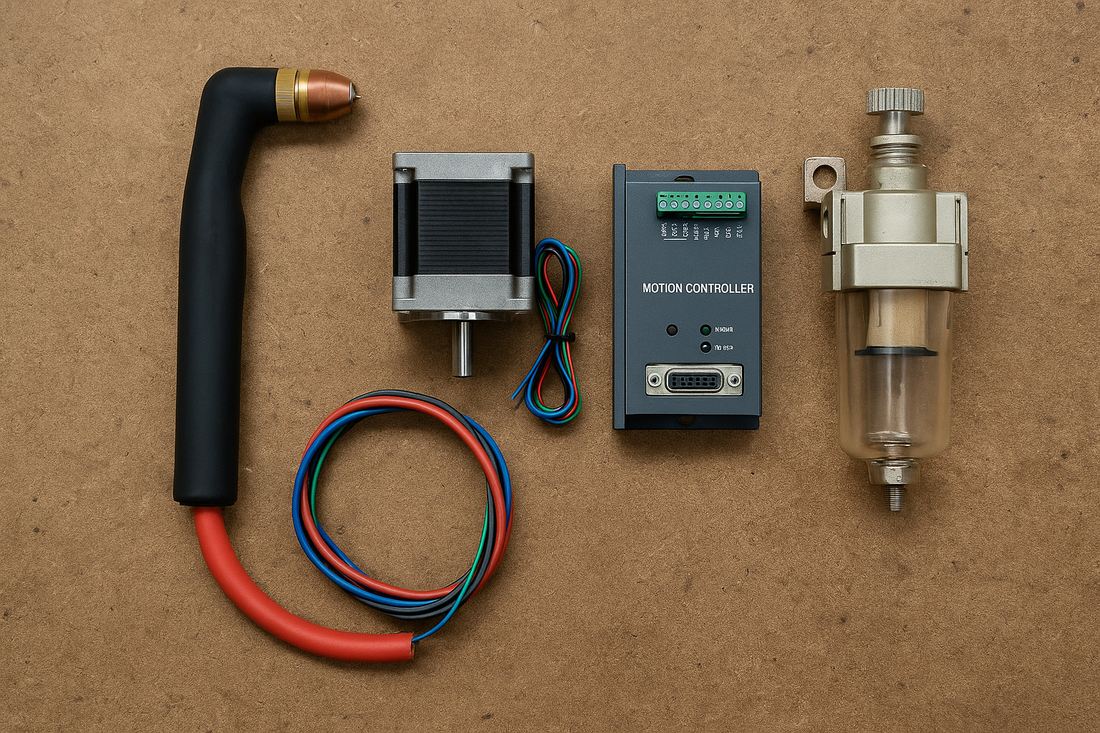

Before we dive into details, it helps to see the big picture. A CNC plasma cutter isn’t just one machine — it’s a combination of systems working together. Each part plays a role in making clean, accurate cuts.

The Core Systems of a CNC Plasma Cutter

1. Plasma Cutter Power Source & Torch

The plasma cutter is the heart of the system — it creates the plasma arc that does the actual cutting. It needs to deliver consistent power, start reliably, and handle the materials and thicknesses you plan to cut. Not all plasma cutters are CNC-friendly, so choosing one with the right features is important.

2. CNC Table and Frame

This is the mechanical platform that supports the sheet metal, allows the different axis’ to move around and holds the torch firmly in place. Its the bones and joints of the machine.

A good CNC table is designed for fast movement and precision, not brute strength. Plasma tables often look lighter than milling machines because they need faster acceleration and quick direction changes, so lightweight is important.

Key options here include whether you use a water table (to trap fumes and sparks) or a downdraft table (to pull smoke away). We will go into more detail in the upcoming parts.

3. Electronics (Motion Control and Motors)

This is what moves the torch with precision and detects any issues. Think circuit boards, motors, power supplies, limit switches, wiring etc.

Without reliable electronics, even the best plasma cutter won’t save your cuts.

4. Computer and Software

Finally, you need a computer and 3 main bits of software to create and run your designs, for example:

- Design software - to design your cut patterns

- CAM software - to turn your pattern into the instructions for your machine (G-Code)

- Machine control software - to send the code to the machine.

5. Air System

Plasma cutting relies on compressed air to create the plasma and blow molten metal away from the cut. Clean, dry air is critical for good cuts and longer consumable life.

You’ll need:

- A compressor with enough CFM (cubic feet per minute),

- A good air filter,

- And a dryer to remove moisture.

The importance of air quality cannot be understated, it is one of the fastest ways to wreck your cut quality and the root cause of a lot of cut issues.