CNC Plasma 101

Part 1: Introduction

CNC Plasma 101 is a practical guide to building your own CNC plasma cutter. It’s designed to help you understand the parts, make informed choices, and start building with confidence — whether you’re new to CNC or looking to take your workshop further.

Part 2: Foundation Knowledge

This section covers the fundamentals of plasma cutting and CNC machines — what plasma is, how it cuts metal, what materials you can work with, and key terms you’ll need to know. A solid foundation to start building your own CNC plasma cutter with confidence.

Part 3: Should You Build or Buy?

This section helps you decide whether to build or buy a CNC plasma cutter. We cover the real trade-offs — cost, skills, time — and break down when it makes sense to buy a machine versus when building your own is the better move.

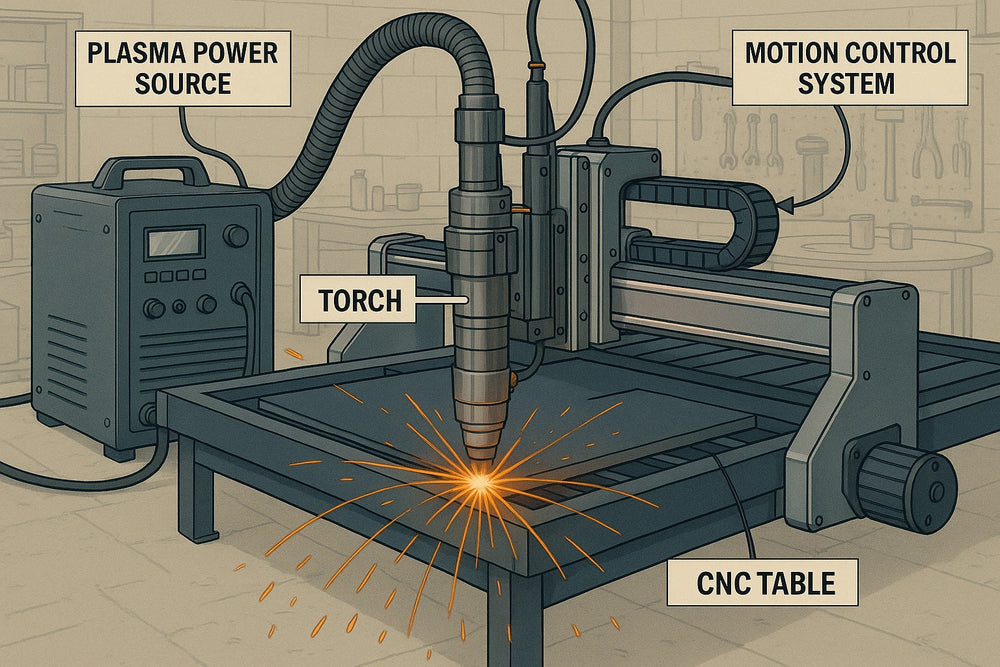

Part 4: System Overview

This section breaks down the core systems that make up a CNC plasma cutter — from the plasma power source to the motion control and air supply. Understanding how these parts fit together is key to planning and building a reliable machine.

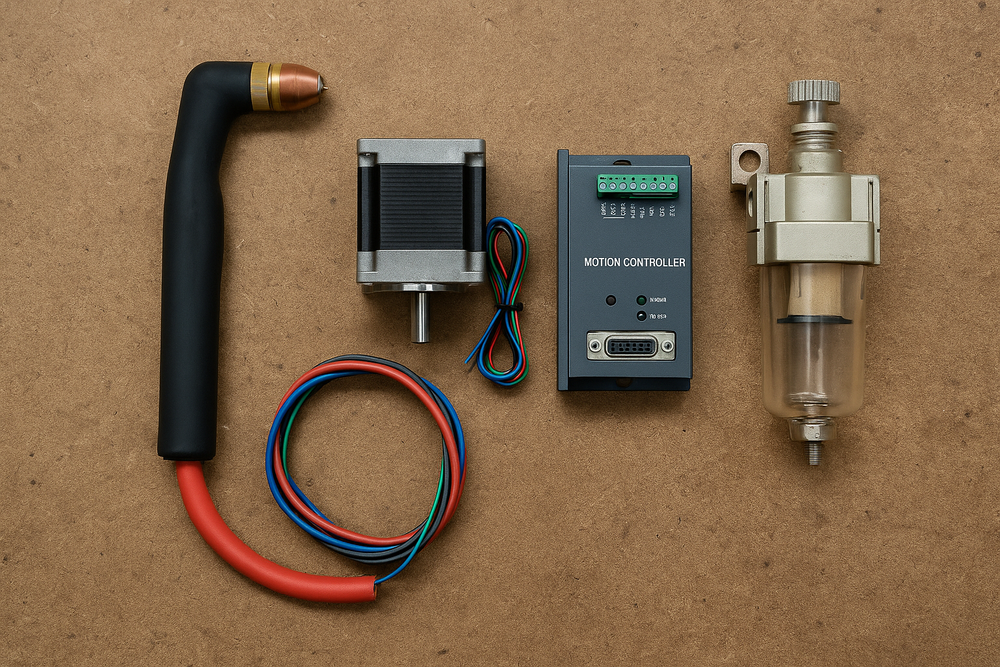

Part 5: Plasma Cutter Selection

Choosing the right plasma cutter is key to a successful CNC build. This section covers start types, torch styles, sizing by amperage, brand pros and cons, and the must-have features for CNC plasma cutting — helping you pick the machine that fits your needs and budget.

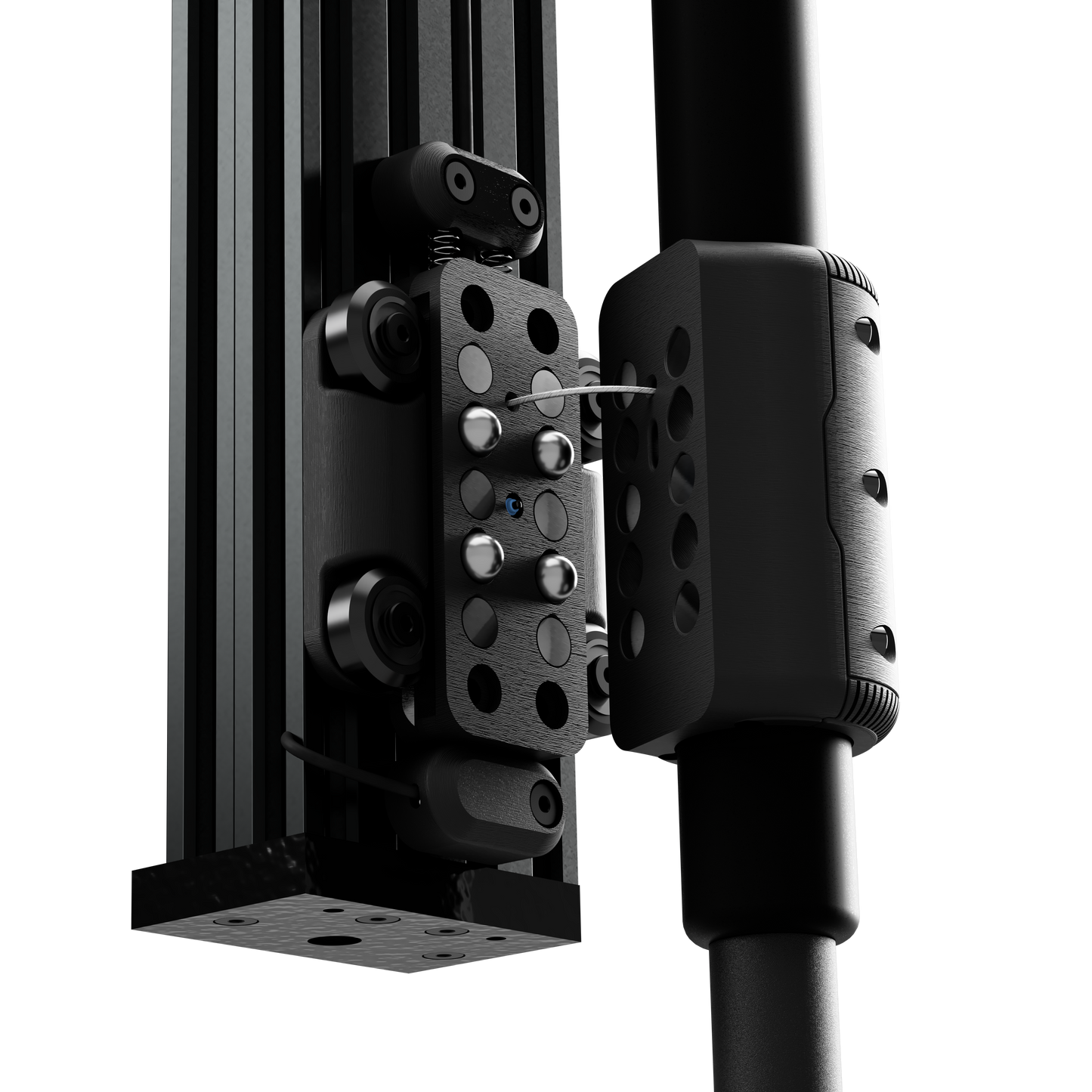

Part 6: Frame & Linear Motion

CNC plasma table design — frame materials, gantry setup, linear motion options, and drive mechanisms. Build a strong, fast, and reliable system.

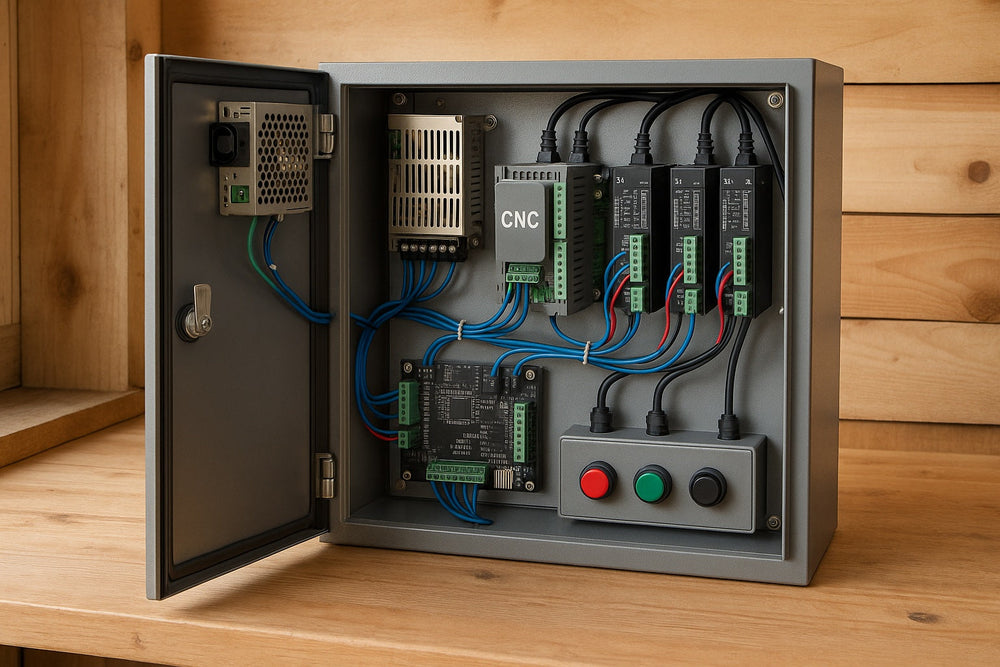

Part 7: Electronics

From motion controllers to torch height control, this section breaks down everything you need to know about wiring up your CNC plasma cutter for accuracy and reliability.

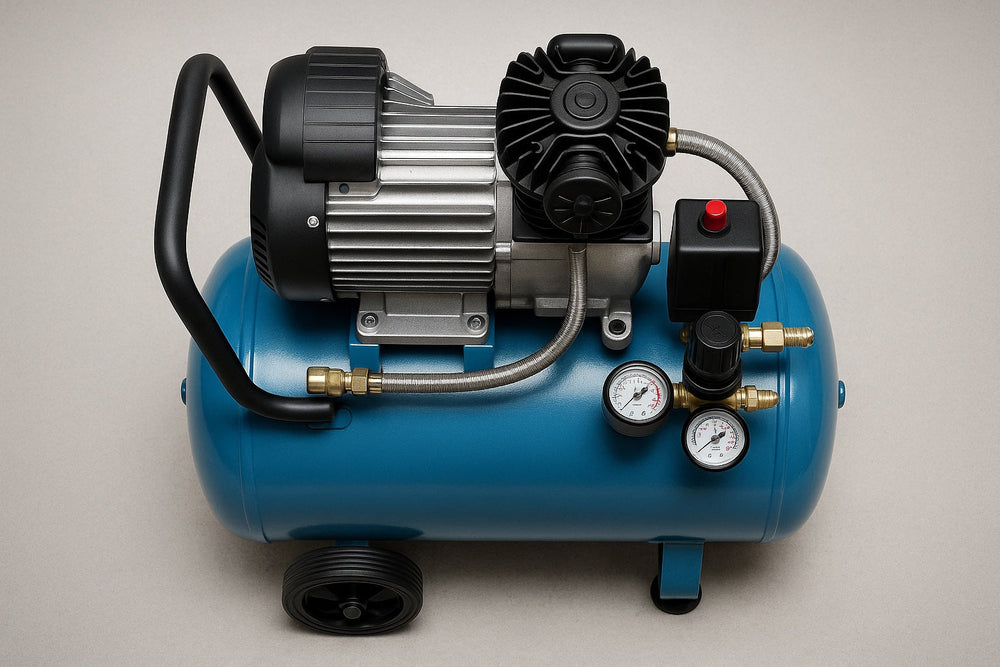

Part 8: Compressed Air System

Choosing the right compressor and air filtration setup is critical for clean cuts and long consumable life. This guide shows you how to size and filter your air system properly.